At TEMA Process, we specialize in advanced mineral drying services, offering bespoke solutions to meet the diverse needs of the mineral industry. Our expertise encompasses a range of minerals, including sand, salt, clay, and more, ensuring optimal drying processes tailored to each unique requirement.

Unparalleled Mineral Dryer Technology

Our state-of-the-art mineral dryer systems are designed to deliver unparalleled efficiency and performance. We understand that each mineral has distinct properties, necessitating a unique approach to drying. Our technology is crafted to preserve the integrity of these minerals, guaranteeing a product that meets the highest standards of quality and purity.

Customized Solutions for Diverse Needs

At TEMA Process, we understand that the mineral industry’s needs are as diverse as the minerals themselves. Our team of experts works closely with clients to understand their specific requirements and challenges. We offer customized solutions that are not just efficient but also sustainable and energy-efficient.

Innovative Design and Sustainable Practices

Our mineral drying systems are not only about performance but also about sustainability. We incorporate innovative design elements that reduce energy consumption and minimize environmental impact. Our commitment to sustainable practices is reflected in every aspect of our drying services, from system design to operational efficiency.

Your Partner in Mineral Processing

Choosing TEMA Process as your partner in mineral drying means choosing a team committed to excellence, innovation, and customer satisfaction. We are dedicated to delivering services that exceed expectations, ensuring that your minerals are processed with the utmost care and precision.

Commitment to Sustainability

At TEMA Process, sustainability is at the core of our operations.Our innovative drying and processing solutions are meticulously engineered to reduce environmental impact, while enhancing efficiency and productivity. By transforming residual products and waste into valuable resources we support the circular economy and contribute to a greener future.

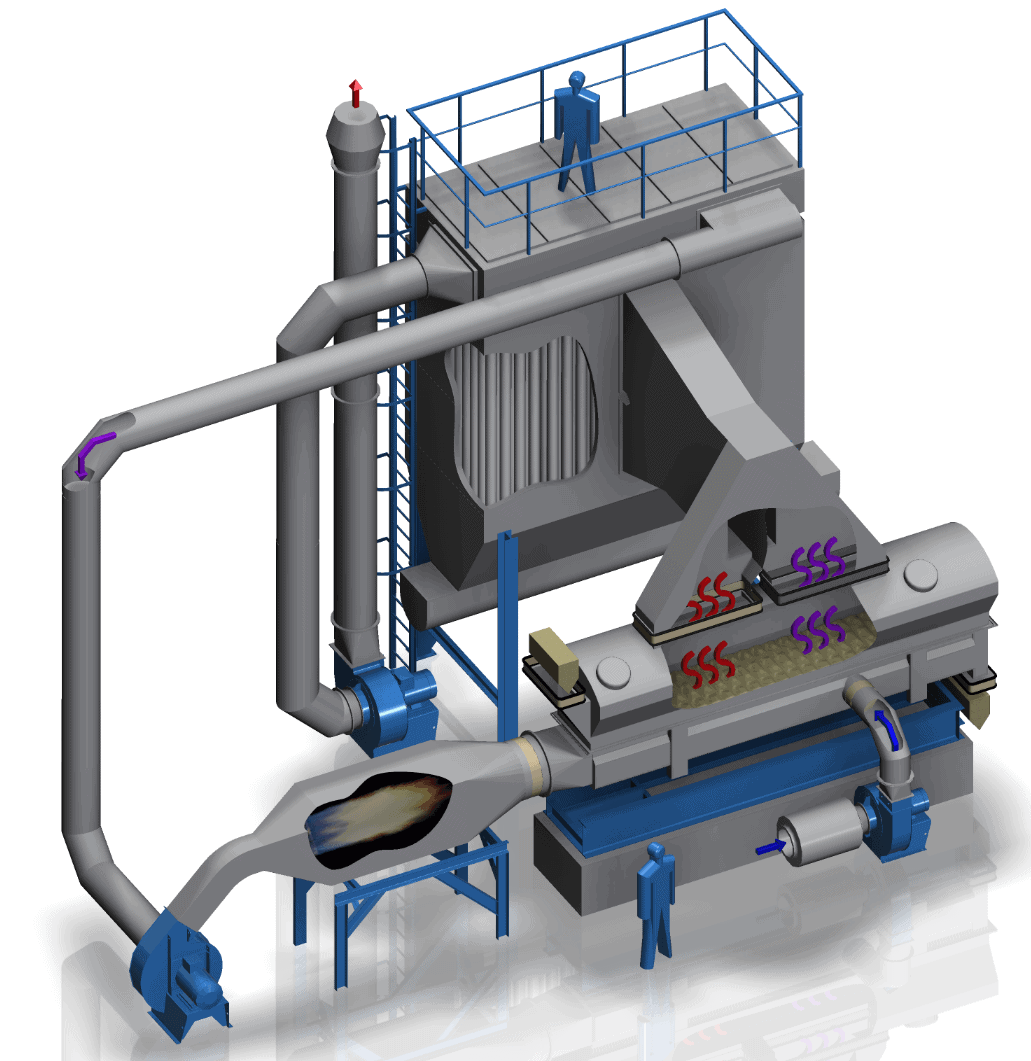

Combined mineral fluid bed dryer/cooler

Fluid bed dryers are specially preferred in mineral drying in combination with after cooling and heat recovery, resulting in better end product quality and very low energy consumptions.

Combined mineral fluid bed dryer/cooler with 2 segment air filtration. Heat recovered from the cooling zone is re-introduced in the drying zone for energy saving.

Shaking fluid bed dryer

Shaking fluid bed dryers are frequently used for the drying of raw natural minerals or pre-processed minerals. The unique TEMA Process shaking drive mechanism allows for a uniform drying result for a large spread in particle size distribution ( 110 microns – 10 mm) , without disruptions of the fluid bed. This shaking design is suitable for capacities up to 100 t/h in a single unit.

Sand Drying: Precision and Purity

When it comes to sand drying, precision is key. Our advanced systems ensure uniform drying, maintaining the consistency and quality of the sand. This process is crucial for various applications, including construction, glass manufacturing, and filtration. Our sand drying services ensure that the final product is free from contaminants and moisture, ready for its intended use.

The TEMA Fluid bed dryers are specially preferred in mineral drying in combination with after cooling and heat recovery, resulting in better end product quality and very low energy consumptions. Combined mineral fluid bed dryer/cooler with 2 segment air filtration. Heat recovered from the cooling zone is re-introduced in the drying zone for energy saving

Salt Drying: Maintaining Essential Properties

In the realm of salt drying, maintaining the salt’s essential properties while eliminating unwanted moisture is a critical aspect. Our mineral dryers are equipped to handle the delicate nature of salt, ensuring that it retains its texture and solubility post-drying. This meticulous process is vital for culinary, industrial, and health applications of salt.

Tema Process supplies advanced fluid beds for salt drying applications ( sea-salt, rock salt , vacuum salt or brines) in a large range of capacities , manufactured in corrosion resistant AISI-316 and other grades.

Clay Drying: Optimized for Versatility

Clay requires a specific drying approach due to its pliable nature and diverse applications in ceramics, construction, and art. Our mineral drying services are optimized to ensure that the clay retains its flexibility and strength, making it suitable for various uses. The precise control of our drying systems ensures that the clay is processed without losing its essential characteristics.

TEMA Process fluid Bed Dryers for Clay, sand, gravel, limestone, salt etc. Long life time, energy savings, low maintenance.

- Heavy duty and robust product transport

- Low energy cost

- Low wear and tear

- Precise control of product end moisture