Microbial Safety in Spices, a top Priority

A variety of microbial reduction techniques are routinely employed within the industry for reduction of pathogens. These techniques include: fumigants (ethylene oxide and propylene oxide), steam and irradiation. Each technique has advantages and limitations in effectiveness, quality impact and consumer acceptance.

Natural sterilization/pasteurization with pure steam has gained significantly in popularity with the introduction of the continuous HT-ST “In-Flow” steam decontamination process.

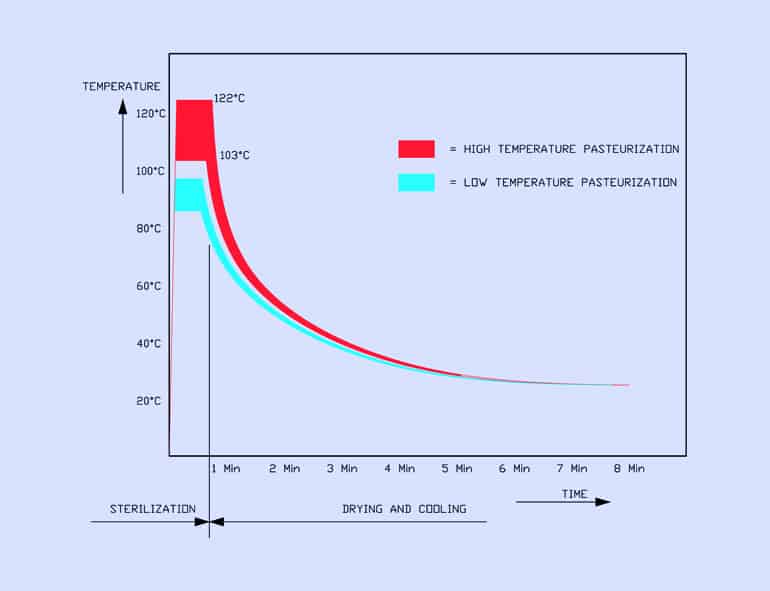

The very short contact (20-40 seconds) with high pressure steam at a temperature that may vary between 102°C and 122°C makes it possible to decontaminate heat sensitive herbs, powder and spices without adverse effect on quality.

Suitable for spices, herbs, botanicals, seeds, whole products and ground products.

Microbial Safety in Spices, herbs, seeds and nuts

A variety of microbial reduction techniques are routinely employed within the industry for reduction of pathogens. These techniques include: fumigants (ethylene oxide and propylene oxide) and irradiation. The world is changing, Consumers Want Healthy Foods which are not treated with a process that possible leave behind a chemical residue or create toxins. Therefor the Natural steam sterilization/pasteurization with pure steam has gained significantly in popularity. The very short contact (20-40 seconds) with high pressure steam at a temperature that may vary between 102°C and 122°C makes it possible to decontaminate heat sensitive herbs, spices and seeds without adverse effect on quality.

Tema Process Natural steam sterilizer

Watch our brand new video about the natural steam sterilizer

Specially made for:

- Spices

- Herbs

- Seeds

- Nuts

- Grains

- Botanicals

- Dried vegetables

- Whole products

- Ground products

Sterilization and pasteurization of spices, herbs and grains

Our decontamination plant/machine is designed for the effective sterilization and pasteurization of spices, herbs, and grains. We focus on building high-quality, reliable machines. The process includes development, rigorous testing, installation at your site, and continued support with spare parts availability.

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety

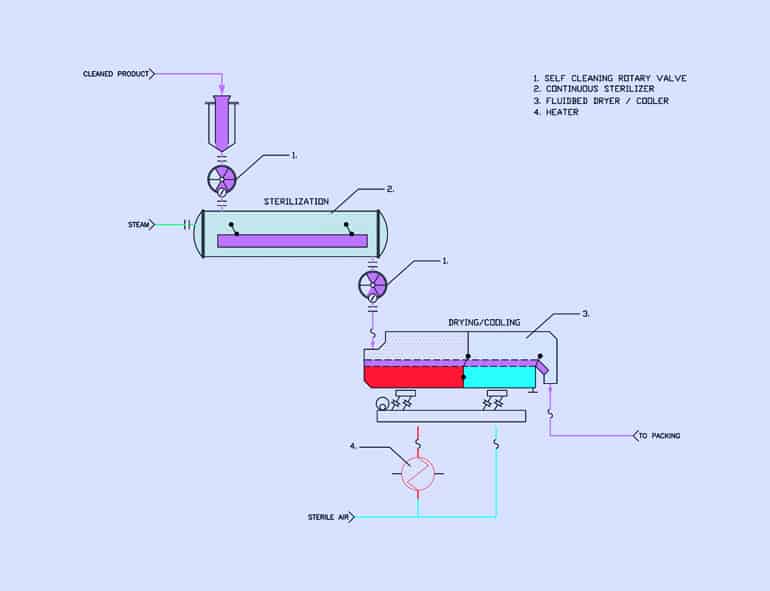

Process description

Natural ST-HT steam sterilization / pasteurization for spices, herbs & botanicals, dried vegetables, seeds and nuts by TEMA Process B.V. The continuous process uses a very special continuous autoclave with inside a so-called shaking bed conveyor and self cleaning rotary valves for respectively product feed into and out off the pressure vessel.

The process is further identified by a sanitary fluid bed dryer/cooler, using sterile filtered air to bring the moisture content of the treated product accurately to the desired final moisture content.

Automatic cleaning in place (C.I.P.) provides for quick change from one product to another. The total process takes only 30 seconds for sterilization plus 7 minutes for conditioning. With the continuous process the product will not be subjected to a temperature above 55 degree C, longer than 60 seconds.

The first multifunctional plant has been installed in the Netherlands in 1990. Continuous steam decontamination plants are in operation in Holland, Germany, Hungary, Poland, Bulgaria, USA, Brazil, India, Korea, Japan, Vietnam, Malaysia and China.

Basic scope of supply steam sterilizing plant

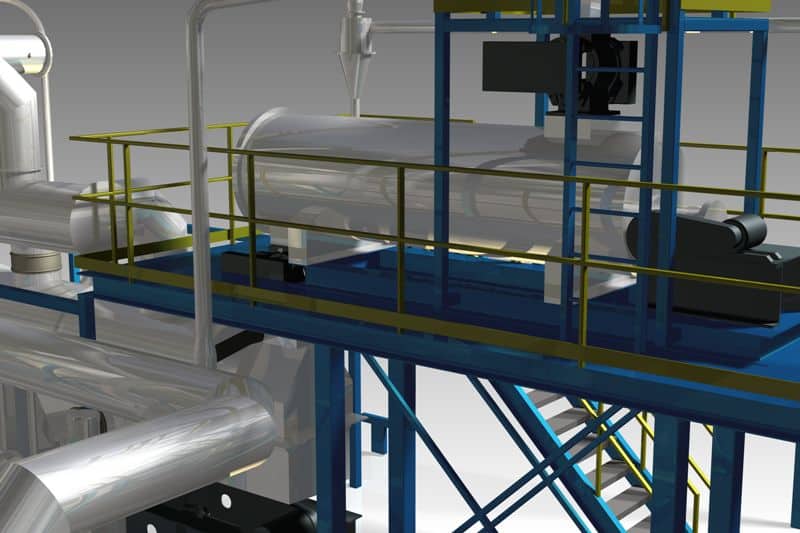

- Sterilizer, complete with support frame, platform and staircase

- Wet scrubber/ Cleaning in Place unit for sterilizer

- Fluid bed dryer/cooler

- Sterile air supply unit for fluid bed dryer/cooler

- Dust separator for exhaust air from fluid bed dryer/cooler

- Central control panel (PLC and suitable for data acquisition for HACCP)

- Instrumentation

- Spare parts for the first year of operation

- Supervision of erection and commissioning plus training of operators

Optional deliveries

- Pneumatic product feed to sterilizer using sterile air from filter unit

- Pneumatic product discharge from fluid bed dryer/cooler to packing room using sterile air from filter unit

- Finisher to turn agglomerates back into a free flowing powder

Capacities

- High temperature plants can be supplied in capacities ranging 500 – 3000 kg/h

Want more info? download our technical sheet

Gain a comprehensive understanding of our diverse product range through our detailed technical sheets. Available in multiple languages, these sheets offer key insights to inform your decisions.

Enhance your knowledge with images included in our sheets that help elucidate the processes and their applications, making it easier for you to visualize and grasp the practical aspects of our products.

Plants for pasteurization at specific temperatures

Pasteurizer – Dryer Cooler Installation

These plants are designed for rather clean hand picket and machine dried products such as herbs, seeds and nuts, e.g. for cinnamon, Parsley, garlic

flake, pistachio nuts, almonds, sun flower seed, dried vegetables etc.

Pasteurizer – Dryer Cooler Installation

The low temperature pasteurizing plants have basically a shaking pasteurizer which is directly connected to a shaking fluid bed dryer/cooler using

ambient superheated steam for pasteurization and sterile filtered air for drying and cooling. The pasteurizing vessel has a perforated bed plate on which the product proceeds forward. The process is controlled by a PLC with data acquisition.

interior of continuous Autoclave

A variety of microbial reduction techniques are routinely employed within the industry for reduction of pathogens. These techniques include: fumigants

(ethylene oxide and propylene oxide), steam and irradiation. Each technique has advantages and limitations in effectiveness, quality impact and consumer acceptance.

Exterior of Autoclave with product feedhopper and Rotary Valve

Natural sterilization/pasteurization with pure steam has gained significantly in popularity with the introduction of the continuous HT-ST “In-Flow”

steam decontamination process. These plants are multifunctional plants for heavy polluted sundried products to be processed at temperatures up to 122 °C. The very short contact time (20-40 seconds) with high pressure steam at a temperature that may vary between 102 °C and 122 °C makes it possible to decontaminate heat sensitive herbs and spices without adverse effect on quality.

PasteurizerSterilizer – DryerCooler Installation and Dust Separator