Lithium Chloride (LiCl) is a highly effective liquid desiccant for precise humidity control. In a liquid desiccant dehumidifier, the LiCl solution continuously circulates between the dehumidifier and the regenerator to maintain stable air conditions.

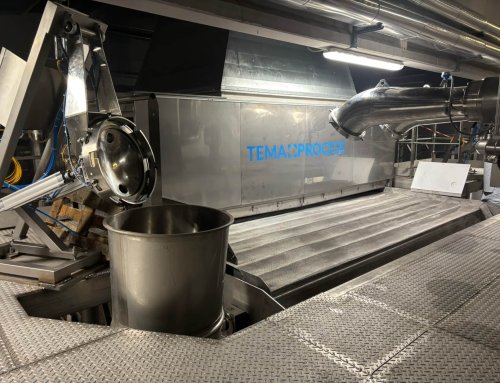

TEMA Process designs, builds, and installs its own LiCl dehumidification systems, and supports customers with installation and commissioning worldwide.

With the right maintenance, these systems remain highly energy-efficient for drying and conditioning air.

This article is a practical, customer-friendly guide to help you:

- Reduce Lithium Chloride consumption (less top-up due to fewer losses)

- Reduce build-up and corrosion/rust formation

- Extend component lifetime (pumps, frames, ducts, heat exchangers, valves)

This checklist can also be used for installations from other brands. TEMA Process can support troubleshooting, improvements, and retrofits for non-TEMA systems as well.

End-to-End Delivery — From Early Detection to Leak-Tight, Energy-Efficient Operation

Leak prevention works best when you combine (1) consistent inspection, (2) good containment design, (3) carryover control, and (4) fast corrective action. TEMA Process can support with:

- Leak and carryover risk scan (new build or retrofit)

- Review of piping, seals, overflows, drain points, and containment

- Optimization of droplet separators/mist eliminators and drainage

- Monitoring and alarm philosophy (levels, trends, imbalance)

- Service support, training, SOPs, and maintenance shutdown support

- On-site installation/commissioning support worldwide

How to Minimize LiCl Loss

In practice, there are two main routes: (1) mechanical leakage and (2) carryover (droplets entrained and transported with the air stream).

1) Early detection: spot crystallization before it becomes a “real leak”

White/grey crystal residue is often the first sign of a minor leak or local droplet impact. If you see it, locate the source and act immediately—waiting typically increases damage and total LiCl loss.

Recommended inspection frequency

Weekly: general visual inspection

Monthly / during maintenance shutdown: detailed inspection of critical points

2) Mechanical leaks: structurally address the typical leak points

Typical leak points

- Pump shaft seals, flanges, threaded/compression fittings

- Sight glasses (bull’s eye), drain valves, tank penetrations

- Filter housings after maintenance (incorrect assembly or damaged seals)

Practical prevention

- Reduce threaded joints and unnecessary flanges where possible; use robust connections

- Select seals/gaskets suitable for chloride solutions and operating temperatures

- Design for controlled containment: drip trays + routed drainage to a safe collection point

- Make “known risk points” part of a fixed inspection route

3) Prevent carryover: droplet separation is both a performance and leakage factor

Even when the skid is perfectly sealed, LiCl can still be lost via droplet carryover. Mist eliminators only perform as intended when gas velocities are within design limits and drainage is effective—otherwise re-entrainment can occur.

What to check

- No visible carryover downstream of the droplet separator

- Good sealing of inspection hatches and top cover

- Proper drainage: captured LiCl must drain away without being picked up again

Practical Inspection Checklist (Customer Guide)

1. General visual inspection (weekly)

☐ Inspect the entire installation for:

- Crystallization (white/grey residue)

- Dripping, wet spots, discoloration

- Corrosion on steel parts, flanges, or frames

Crystallization is often the first indication of a minor leak.

2. Piping and connections (monthly)

☐ Inspect all:

- Flanged connections

- Threaded and compression fittings

3. Bull’s eye / sight glasses

☐ Glass intact (no cracks/discoloration)

☐ Seals dry and undamaged

☐ No leakage around the sight glass

4. Isolation between pump and pump sump

☐ No LiCl traces around the shaft or flange

5. Droplet separators – dryer and regenerator

☐ Visual inspection droplet separator – process air outlet: no breakthrough/carryover visible

☐ Visual inspection droplet separator – process air inlet: no breakthrough/carryover visible

☐ Inspection hatch sealing OK

☐ Top cover sealing OK

6. Heat exchanger

☐ Inspect flanged connections and LiCl circuit connections

☐ No leakage, corrosion, or crystallization

☐ Where applicable: check steam condensate for LiCl breakthrough

7. LiCl filter housing

☐ Housing dry and clean

☐ Cover and seals correctly installed

☐ No leakage after filter replacement

8. Sealing caps on drain valves

☐ All valves fitted with sealing caps

☐ Caps intact and properly tightened

☐ No leakage via vent or drain points

9. Action in case of deviations

☐ Report deviations immediately

☐ Do not leave leaks “temporarily unresolved”

☐ Record and correct the root cause

☐ Perform re-inspection after repair

✔ Important

- Keep a logbook of inspections and observations

- Respond immediately to small leaks—they can escalate quickly

- Less leakage = less build-up/corrosion = longer component lifetime

Why this also helps energy efficiency

A clean, leak-tight liquid desiccant installation (no carryover, no crystallization, seals in good condition) keeps performance stable over time. TEMA Process systems use a LiCl solution as the absorbent and are positioned as energy-efficient and environmentally friendly solutions.

Let’s Talk

Do you see LiCl loss, crystallization, duct contamination, recurring seal issues, or corrosion spots? TEMA Process can support you worldwide with inspection, diagnosis, and a targeted improvement/retrofit plan—for TEMA installations and for systems from other brands—to stop leakage structurally and deliver the key benefits: lower LiCl consumption, less build-up/corrosion, and longer component lifetime.