In meat processing, temperature control gets a lot of attention, but humidity control is often the missing piece. When humidity rises, you start seeing the classic symptoms: condensation on cold products, water dripping from ceilings, fogging and even icing in certain zones. These moisture issues don’t just look bad; they can increase hygiene risks, disrupt production, and create an uncomfortable work environment.

TEMA Process designs ventilation and dehumidification solutions specifically to keep the dew point under control, because if you control dew point, you control condensation.

Why condensation happens

Air always contains some moisture. The warmer the air, the more moisture it can hold. In a meat plant, conditions constantly change—outside weather, frequent wash-downs, people working, and different products moving through the facility. Many plants mainly steer on temperature, but these factors can still push relative humidity up.

Condensation occurs when the dew point temperature of the air becomes higher than the temperature of a surface or product. In practice: chilled meat enters a warmer processing room, and moisture from the air turns into water droplets on the cold product (and on equipment, ceilings, and pipes).

TEMA Process addresses this by keeping the dew point below the temperature of any surface in the processing area, preventing condensation and reducing the risk of moisture-driven microbial growth.

What a ventilation + dehumidification system changes

A properly engineered system does more than “dry the air.” It stabilizes your processing climate by controlling airflow, temperature and humidity to keep conditions consistent—despite daily wash-downs and shifting production loads.

The benefits in meat processing environments typically include:

• Elimination of condensation on cold products

• Prevention of water dripping from ceilings

• Reduction in electrical failures (less moisture-related stress)

• A more comfortable, healthier climate for workers

• Energy-efficient operation that supports lower operating costs and sustainability goals

How TEMA Process dehumidification works

TEMA Process uses a liquid desiccant approach based on a Lithium Chloride (LiCl) salt solution. In simple terms: LiCl has a strong affinity for water, so it absorbs moisture from the air very effectively.

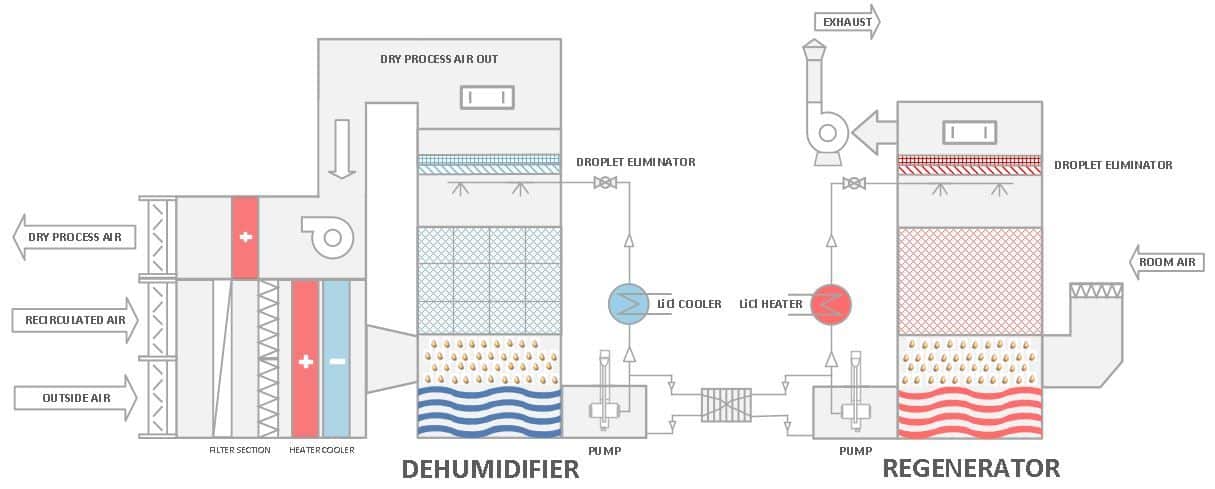

1) Moist air enters a countercurrent dehumidifier

Process air flows through a countercurrent dehumidifier where it meets the sprayed LiCl solution. The air is dehumidified (or humidified if needed) to maintain equilibrium—meaning the system can precisely steer the outlet condition.

2) Salt concentration controls the outlet humidity

Because of this equilibrium behavior, the sprayed salt concentration directly controls the outlet air relative humidity—a practical way to achieve stable, repeatable conditions in large production areas.

3) Temperature and humidity can be adjusted independently

By cooling the salt solution before spraying, the system can also cool the air. That means air temperature and humidity are controlled in the same system, while still being adjustable independently.

4) Regeneration restores drying capacity continuously

As the solution absorbs moisture, it becomes diluted. To restore its drying power, it is pumped to a regenerator where the solution is heated, releasing the moisture into an outside air stream and exhausting it. The solution circulates continuously between dehumidifier and regenerator for stable performance.

5) Added practical advantages of LiCl

TEMA Process notes LiCl is chemically stable, non-toxic, non-vaporizing, and also acts as a biocide to mold, bacteria and micro-organisms, plus it is an effective antifreeze.

What TEMA Process delivers

For meat processors worldwide, implementation matters as much as technology.

• Custom-designed solutions to match your product flow, layout and operating conditions.

• Installation and commissioning support worldwide, via a broad network of engineers for on-site mechanical, electrical or burner-related work.

• On-site training so operators and maintenance teams know how to run the system at peak performance and lowest operating/maintenance cost.

• Service & spare parts support, including inspections, repairs, annual checks, and preventative maintenance guidance to reduce downtime and extend equipment lifetime.

Talk to a dehumidification specialist

If condensation, wet floors, fogging, or humidity swings are impacting your meat plant, we can help you quantify the impact and define the right solution for your layout, production conditions, and target climate.

Feel free to contact one of our specialists for a no-obligation consultation to explore the possibilities.