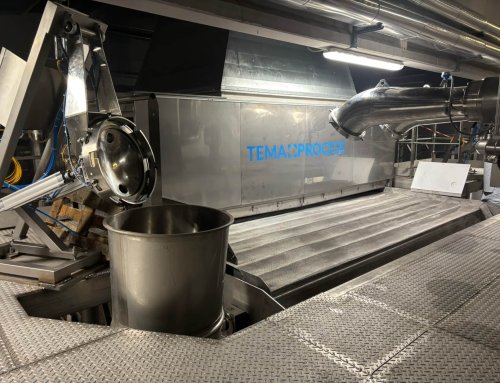

Carbon black production: This is a process where hydrocarbon feedstock (heavy fuel oil) is converted into carbon black. Hydrocarbon fuels, oxidants, additives, and the primary feedstock are injected into a horizontal refractory reactor where they combust with a defect of oxygen. As a result of the incomplete combustion the carbon black is formed. The carbon black is then pelletized into dense spheres to facilitate handling and shipping. To pelletize the carbon black, water with a small amount of binder is added to the carbon black in a mixer. The wet pellets are then dried in a Tema Process fluid bed dryer.

Carbon black recovery from tyres: Tire recycling has become a necessity because of the huge piles of tires that represent a threat to the environment. The used tires represent a source of energy and valuable chemical products. By thermal decomposition of rubber, it is possible to recover the useful compounds like the carbon black from the tyres. Also this recovered carbon black is dried and cooled on a Tema Process fluid bed dryer.

The most common use (70%) of carbon black is as a pigment and reinforcing phase in automobile tires. The balance is mainly used as a pigment in inks, coatings and plastics.