With an investment of 30 million euros, the Life for Tyres plant in Puertollano (Ciudad Real) plans to recycle some 27,000 tons per year, 9% of the tires used annually in Spain.

Carbon black is a material produced by the incomplete combustion of heavy petroleum products. Traditionally Carbon Black (CB) has been used as both a reinforcing agent and filler in automobile tires. Along with better understanding of CB’s unique properties as a material, it is presently used in a much wider range of applications across a large variety of products – car tires, conveyor belts, inks, plastic pipes, rubber mats, shoe soles and so forth.

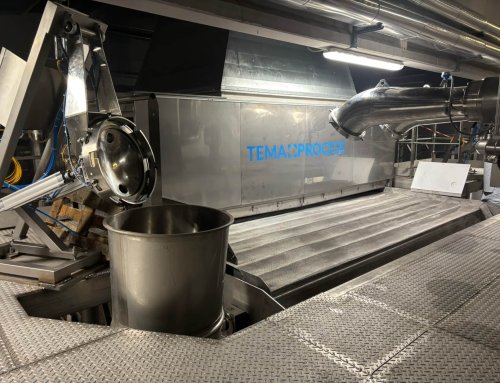

CIRCULAR ECONOMY: Recovered Carbon Black rCB rCB it is a substitute of the virgin Carbon Black obtained from fossil fuels using end-of-life tires instead of fossil oil as a resource material. The process generates oil, gas, steel and recovered Carbon Black (rCB) as final products. Especially the rCB can be used to replace the virgin Carbon Black in various applications. This ‘black gold’ must undergo several processing steps after pyrolysis, like grinding, pelletizing, drying and packing, before it can be used as recovered Carbon Black (rCB). The energy-saving and environmentally-friendly carbon black Tema Process fluid bed dryer: A continuous Tema Process fluid bed system is a machine in which a continuous flow of “wet” pellets is conveyed over a perforated bed. Hot drying air is blown through the holes of a perforated plate. The wet solids are lifted from the bottom and causes the solids to behave as a fluid. The air velocity is adjusted to keep the moving layer of material fluidized. Conveying of the product is achieved by means of a low-frequency, high amplitude shaker mechanism. The “Shaking” motion plug flow of the Tema fluid bed, allows first-in, first-out drying of products and well-mixed fluidization, which covers the entire spectrum and is able to accurately control the spread of residence time.

– Low energy consumption

– ATEX Compliance

– Accurate control of the residence time, product is dried uniformly

– Gentle on sensitive materials (no friction)

– Low operating costs

– Cooling section integrated in dryer

– Small footprint

– Process flexibility

– Reliable system, less downtime