The successful installation of a fluid bed drying system starts with a structured and well-planned erection process.

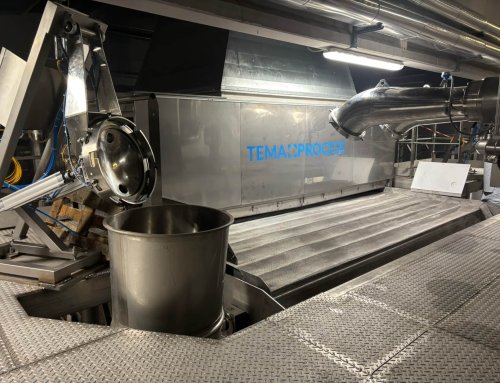

At site, foundations and steel support structures are prepared according to layout drawings. The fluid bed dryer is then positioned and aligned, followed by installation of internal components such as the air distribution plenum, perforated air deck and discharge sections.

Next, the process air system is erected, including fans, heaters and ducting with expansion joints to ensure reliable airflow and thermal stability. The baghouse filter is installed on its steel structure, after which filter bags, cages and the pulse-jet cleaning system are mounted.

Finally, all mechanical, electrical and pneumatic connections are completed, enabling safe pre-commissioning and start-up. This systematic approach ensures reliable performance, efficient dust separation and long-term operational stability.