Breadcrumbs are produced in a continuous, controlled process to ensure uniform color, texture, and particle size. A specially formulated dough—yeast-fermented or non-yeasted for lighter crumbs like Panko—is mixed from wheat flour, water, salt, and optional ingredients. The dough is formed into sheets or blocks with rollers or extruders and baked in a tunnel oven, where moisture is reduced and structure and color are developed.

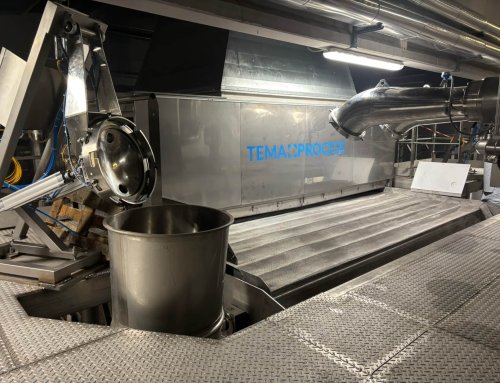

After baking, the product is cooled and broken down in a Tema Process Bread Mill. The crumb still contains too much moisture, so it is dried in a Tema Process fluid bed dryer/cooler. Heated air gently fluidizes the crumbs for uniform drying while preventing sticking, dust, and breakage. Correct moisture is achieved by tightly controlling inlet temperature, airflow, bed depth, and residence time—avoiding both under- and over-drying.

The product then enters the integrated cooling section, where ambient or cooled air lowers the temperature to prevent condensation and maintain crispness. Finally, crumbs are screened to the required particle size; oversize is milled again and fines are adjusted as needed. The finished product is hygienically packaged and quality-checked for moisture, color, size, density, and safety.