The Tema Process ventilation and dehumidification solution

Humidity problems in meat processing plants. Humidity, condensation and water are a serious risk. Both temperature and humidity levels inside a meat processing plant should be kept as constant as possible. It sounds simple, but the following characteristics continuously vary: outside weather conditions, rooms are periodically cleaned using water, personnel are at work and different products are processed. As most meat factories only control temperature, [...]

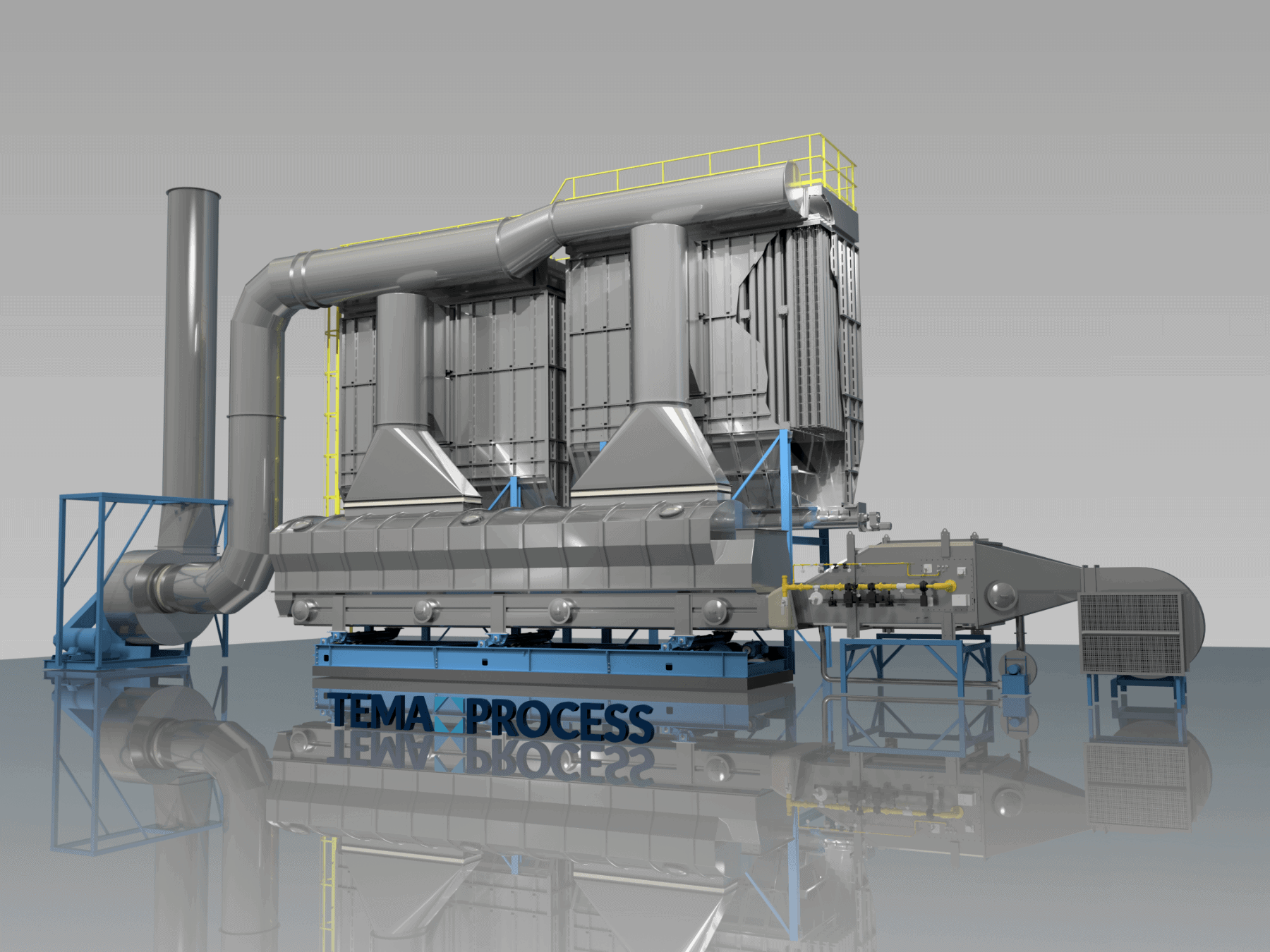

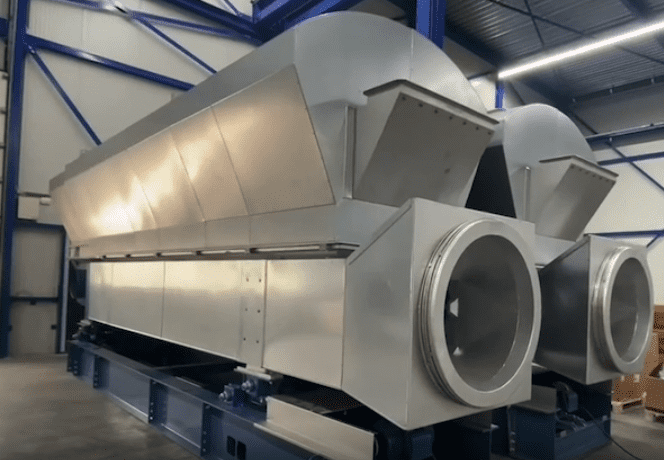

Tema Process Belt dryers & coolers, how does it work?

A continuous conveyor belt dryer system is a particularly gentle thermal treatment for your product. It can dry large quantities with high moisture loads, temperature sensitive or brittle products and products which require a long residence time. The dryer is divided into segments (drying zones) in order to create high air velocities with a lower air volume. Fans and heaters can be placed inline or [...]

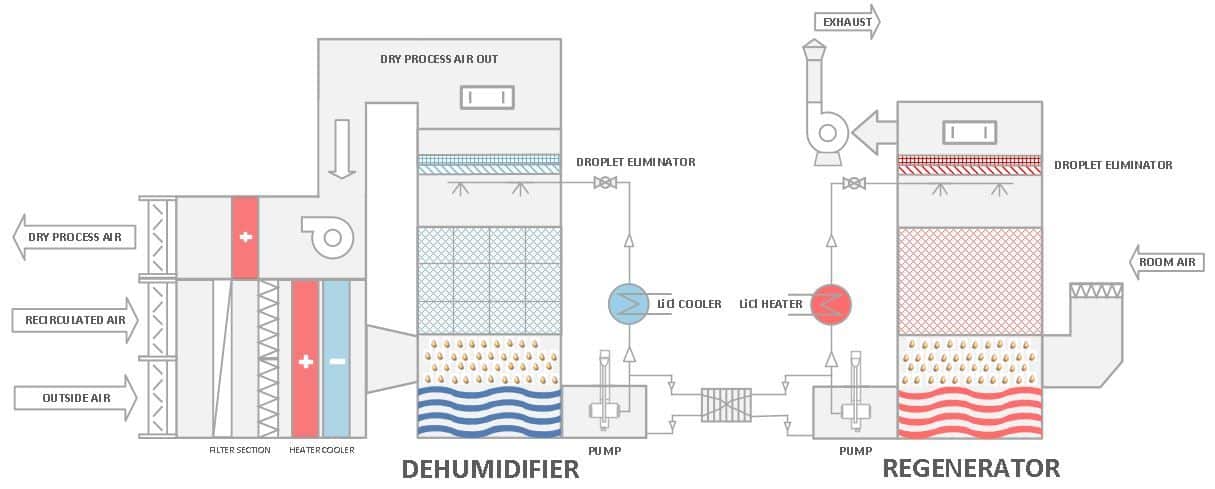

How does our liquid desiccant dehumidifier work?

The Tema Process dehumidifier is using a Lithium Chloride salt solution as absorbent. Lithium Chloride is a very strong salt and has an equilibrium curve which closely follows the relative humidity curve of air. The process air will enter the countercurrent dehumidifier and will be dehumidified or humidified in order to maintain this equilibrium. In other words the sprayed salt concentration will control the outlet [...]

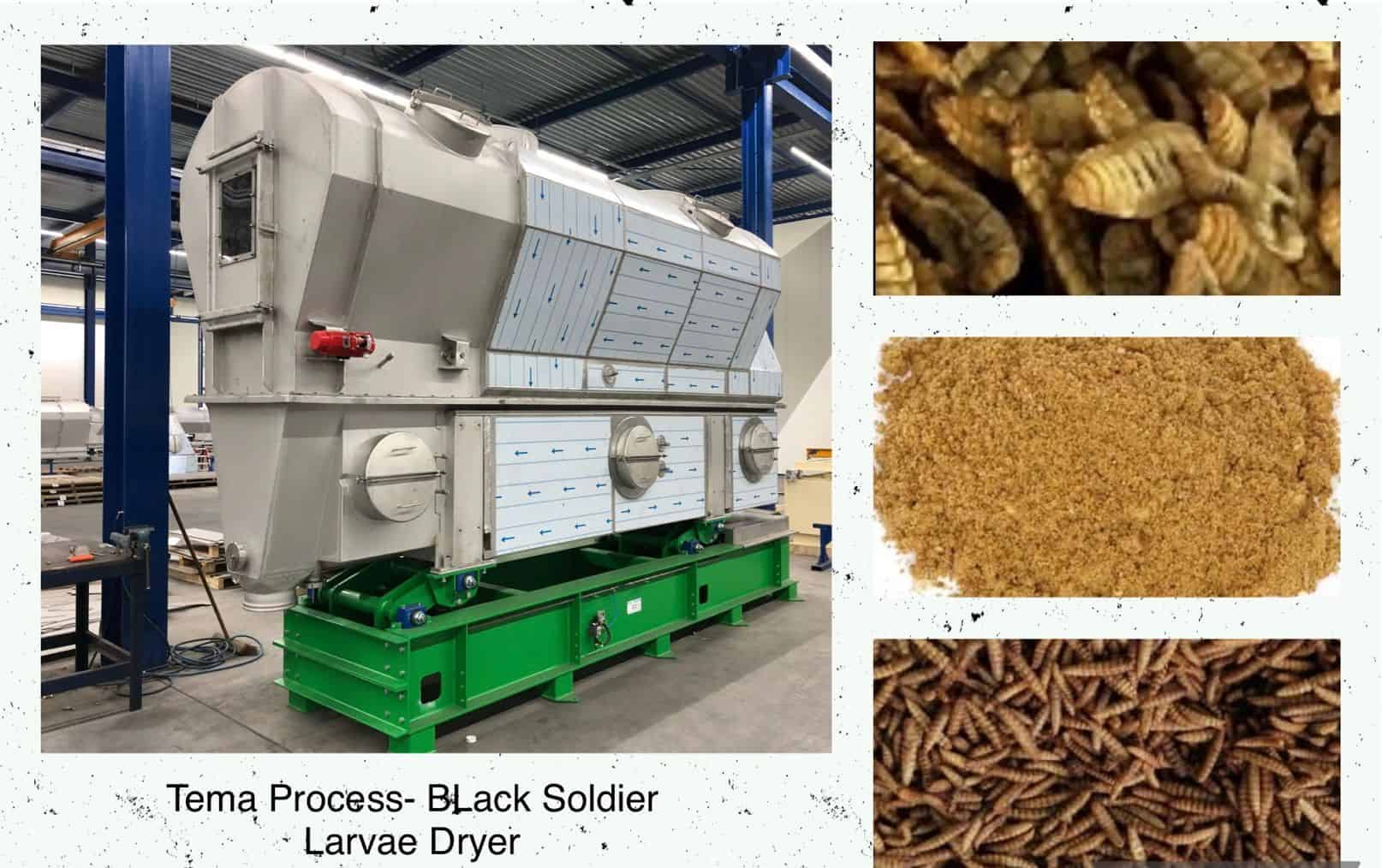

Black Soldier Larvae Dryer

Black soldier fly larvae (BSFL) are used to compost waste or convert the waste into animal feed. The larvae are among the most efficient animals at converting biomass into feed. Black soldier fly larvae (BSFL) are an alternative source of protein for aquaculture, animal feed, pet food and human nutrition. The larvae needs to be dried before packaging and storage. The moisture content of Black [...]

Thermal Treatment Solutions

Fluid Bed Dryers for : Copper Sulfate (CuSO4.5H2O), Bread crumb, Sand & aggregate, Potassium Chloride KCL, Sodium Chloride NaCl, Digestate, Larvae BSF, SLS needles, PE PP Pellets, Lithium hydroxide monohydrate, Lithium Carbonate, Carbon black granules, Granulated fine clay + sand, Ammonium Sulphate (NH4)2.S04, Calcium Nitrate granules (fertilizer), Talc, Sodium sulphate Na2SO4, Lithium hydroxide monohydrate, Polystyrene granules, Wet fibre residue oat, Fungicides / Insecticides, Mono Ammonium [...]

Commissioning organic Fertilizer dryer

With the Tema Fluid Bed Dryer poultry manure, digestate or biomass can be dried and converted into organic fertilizer. The dried product is an excellent plant nutrient. If you wish to live in harmony with nature and make a lasting improvement in your own patch of earth for generations to come, organic fertilizers outweigh chemicals by leaps and bounds.

ThermoSeed: The cleanest seed in the world Vihervakka Lantmannen

Globally there is an increasing demand for sustainable crop production processes. ThermoSeed offers an innovative, highly efficient and environmental friendly seed treatment technology with great added value to seed processors and farmers. ThermoSeed was developed in Sweden in the nineties and has undergone rigorous testing in a wide range of crops under various climatic conditions worldwide with remarkable and consistent results. Nowadays 60.000 tons of [...]

Sand Dryers for India – Ready for shipment

Tema Process is the leading international manufacturer of fluidbed drying systems. The company owes its strong growth to consistently delivering high quality consultancy, process improvements and efficient tailor-made solutions for a range of industrial sectors, including the food, feed, chemicals, minerals and recycling industries.

New Digestate Tema Process Dryer!

Digestate is the material remaining after the anaerobic digestion of a biodegradable feedstock. Anaerobic digestion produces two main products: digestate and biogas. The primary use of digestate is as a soil conditioner. The digestate is dried on on a Tema Process Fluid Bed Dryer.

Tema Process: Mineral drying

Mineral drying: sand, talc, limestone, gravel, clay etc. Tema Process Fluid Bed Dryers. […]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety